GREEN CUBESAT PROPULSION

- Integrated turn key propulsion system

- Optimized for volumetric efficiency

- Easy integration with cubesats

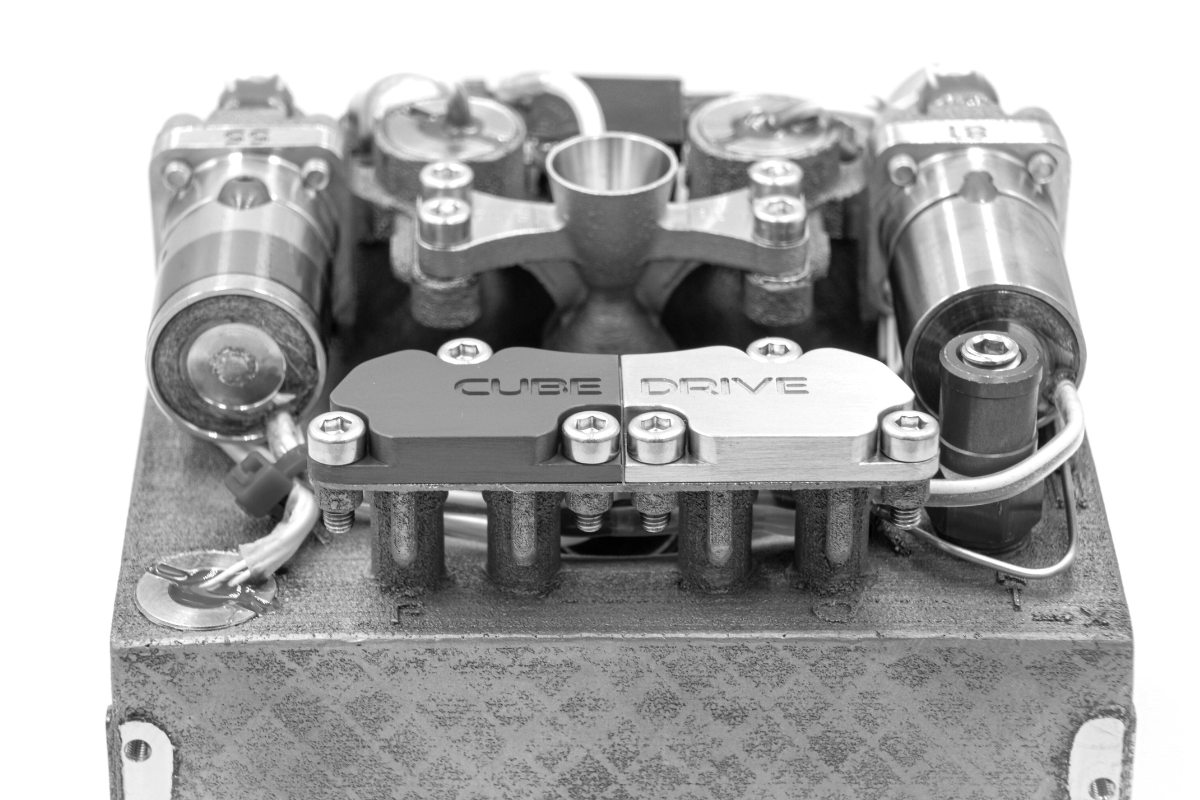

CubeSat propulsion systems and bolt-on collision avoidance kits for ESPA-class satellites. Each CubeDrive includes a B1 thruster, tanks, valves, and control electronics. Structures are 3D printed as a single monolithic piece using Inconel, including fuel and oxidizer tanks. Health monitoring instrumentation includes various thermocouples and pressure sensors.

-

Status

In spaceThruster

One B1 thrusterTotal impulse

95.5 lbf.s

425 N.sMass (dry / wet)

2.14 lbm / 2.58 lbm

970 g / 1170 gDimensions

3.15 x 3.78 x 3.78 in

80 x 96 x 96 mmPropellants

Nitrous oxide (N2O) and

Propylene (C3H6)Tank type

Type 1: All metallic, 3D printedData

CAN bus, RS-485, or RS-422Supply voltage

Digital: 5 to 5.2 VDC, and

Actuators: 12 VDC unregulatedOperational temperature

23°F to 86°F (-5°C to 30°C)Survival temperature

-22°F to 104°F (-30°C to 40°C)

-

Status

In developmentThruster

One B1 thrusterTotal impulse (~)

325 lbf.s

1450 N.sMass (dry / wet)

4.52 lbm / 5.95 lbm

2050 g / 2700 gDimensions

7.87 x 3.78 x 3.78 in

200 x 96 x 96 mmPropellants

Nitrous oxide (N2O)

Propylene (C3H6)Tanks

Type 1: All metallic, 3D printedData

CAN bus, RS-485, or RS-422Supply voltage

Digital: 5 to 5.2 VDC, and

Actuators: 12 VDC unregulatedOperational temperature

23°F to 86°F (-5°C to 30°C)Survival temperature

-22°F to 104°F (-30°C to 40°C)

“It is revolutionary to the CubeSat market. There are alternatives out there, but nothing that suit a 3U CubeSat like this.”

— Maarten Engelen, CTO, Hiber

CubeDrive Green Propulsion

- 1N

-

Available in various form factors, the B1 thruster is currently utilized as the central thruster in Dawn’s CubeDrive propulsion modules and as a modular building block within Dawn's turn-key SatDrive systems. They can be positioned throughout the spacecraft, in clusters, and at various cant-angles. The B1’s assembly includes the thruster body, valves, and control electronics. Thruster bodies are additively manufactured as a single structure using Inconel 718 and include the injector, combustion chamber, and nozzle. Health monitoring instrumentation includes an integrated and isolated thermocouple and chamber pressure sensor. With standard data and power interfaces, thrusters are easy to command and operate.

-

Physical

Thruster dimensions

4.25 x 3.11 x 1.58 in (108 x 79 x 40 mm)Dry mass

0.57 lbm (260 g)Nozzle expansion ratio

100:1Valves

Normally-closed solenoid

Two per thrusterInterfaces

Mounting

Four 3.2mm holes.Performance

Thrust, range

0.10 to 0.29 lbf (0.46 to 1.28 N)Minimum impulse bit

Bi-prop: 0.022 lbf.s (0.1 N.s)

Cold-gas: 0.001 lbf.s (0.005 N.s)Ignition

Spark-based igniterPulse frequency

4 HzRestarts

6,500 per thrusterControl

Operable together or independently

Select your desired quantity

Pair with B20 thrustersFiring modes

Bi-prop & cold-gas. Switch at will. Managed by not engaging the spark-igniterCold-start capable

Yes. Highly repeatable -

DEFINING FEATURES

High-performance propulsion

Experience significant time and power savings by switching to spark-based ignition, allowing you to conduct cold-start to full thrust firings in under 100ms. Achieve high performance exactly when needed by removing sensitive catalysts.

Rideshare friendly

Dawn’s propulsion systems have flown on every SpaceX Transporter mission to date, Starlink rideshare, and Arianespace’s Vega rideshare. Learn more about our safe failure modes and why launchers like what we’re building.

A unified architecture

All Dawn systems use the same highly scalable N2O/C3H6 architecture. Select your desired thruster quantity and thrust class(es), tank size, and interface, then let us do the rest.

Less parts = higher reliability

Propellants are self-pressurizing and don't require external pressurants, high-pressure regulators, or mechanical PMDs. There are no rare-Earth materials, catalyst beds, or proprietary propellants. The result: low part count, low weight, low cost, and high reliability.

Dual firing modes

Unique for rendezvous and proximity operations, all thrusters can operate in both a bi-propellant and cold-gas mode by controlling the spark igniter. Even with large thrusters, achieve tiny impulse bits for RPO, fine pointing, and servicing.

Domestic propellant suppliers

N2O(purity class 2.0) and C3H6(purity class 2.5) are widely available from domestic suppliers. ITAR-free and REACH-compliant, avoid the international supply chain, export control, and cost issues of proprietary propellant blends.

"Dawn’s engineering approach mirrors our own at Lynk, and they are positioned to build at scale."

— Charles Miller, CEO, Lynk

DESIGN, DELIVERY, & SUPPORT 🚀

Mission design

Whether you want orbit insertion, phasing, stationkeeping, debris avoidance, life extension, momentum management, de-orbiting, or all the above, we’ll help you with mission success.

Engineering support

Although our systems all use a unified architecture, we know that satellite builders have different needs. That’s why we give engineering support to all our customers.

Production

High-volume and high-cadence production. State-of-the-art additive manufacturing with lean production methodology. In-house 5-axis machinery and cleanrooms.

Accelerated schedules

Enabled by vertically integrated capabilities of engineering, manufacturing, and testing.

Environmental qualification

In-house hot-fire and hydrostatic test facilities. Access to world-class test facilities for thermal cycling, shock, 3-axis vibration, and radiation testing.

Acceptance testing

In-house vacuum chambers and ambient test setups for hot-fire and full hardware-in-the-loop tests. Standardized and well-defined test procedures and quality assurance plans.

Export

Global export licenses, exporting from New Zealand and The Netherlands. Flown on satellites launched aboard 🇺🇸 and 🇪🇺 vehicles.

Launch-site fueling support

Dawn provides worldwide support for satellite fueling and propellant sourcing, whether at the launch site or your own premises.

On-orbit commissioning

We don’t just deliver you hardware, a few ICDs, then leave you to it. We are a full-service partner by your side the entire way.